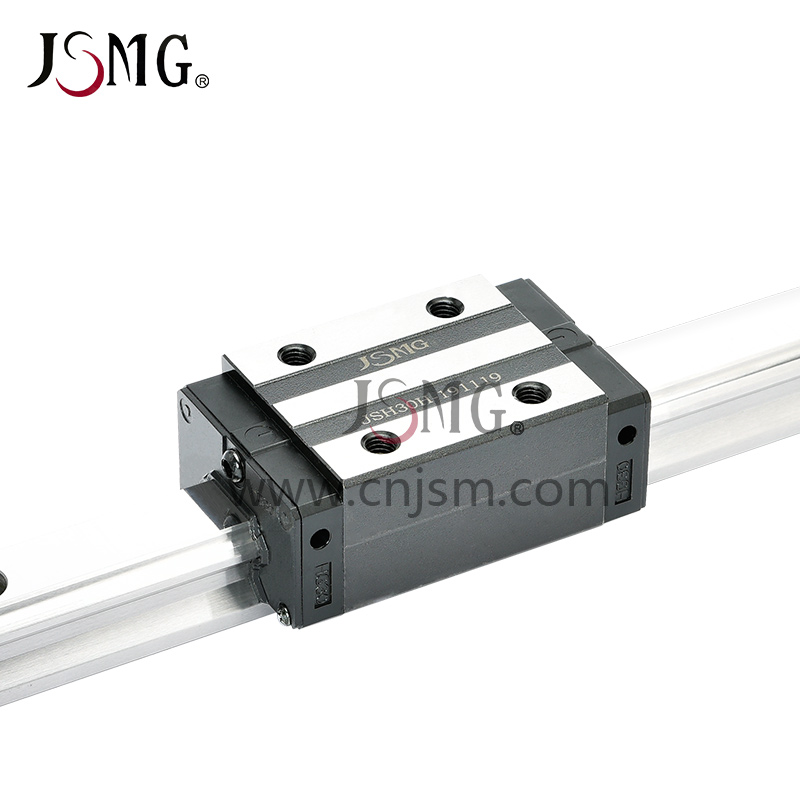

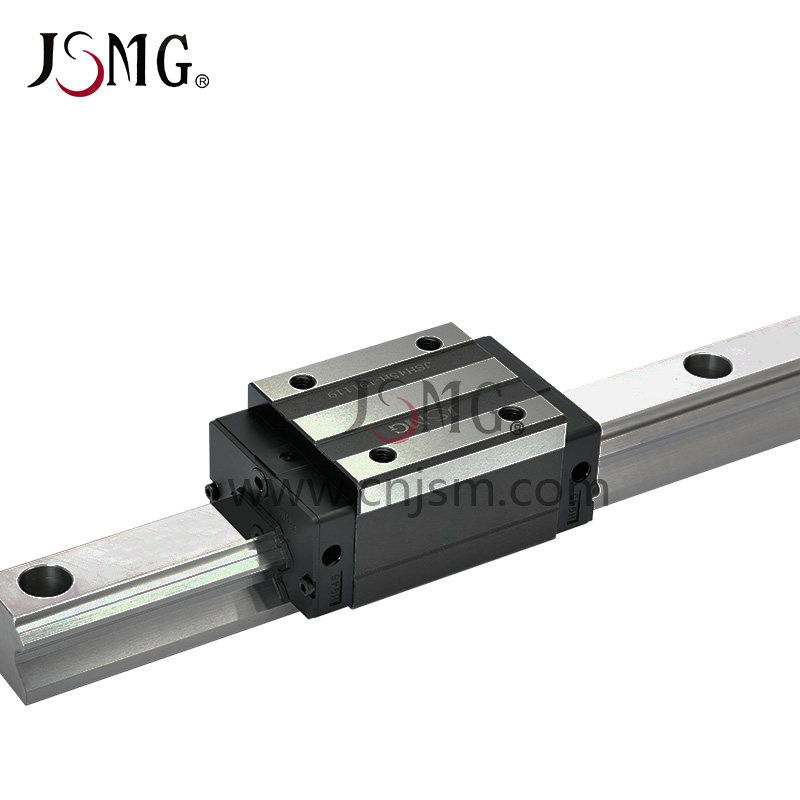

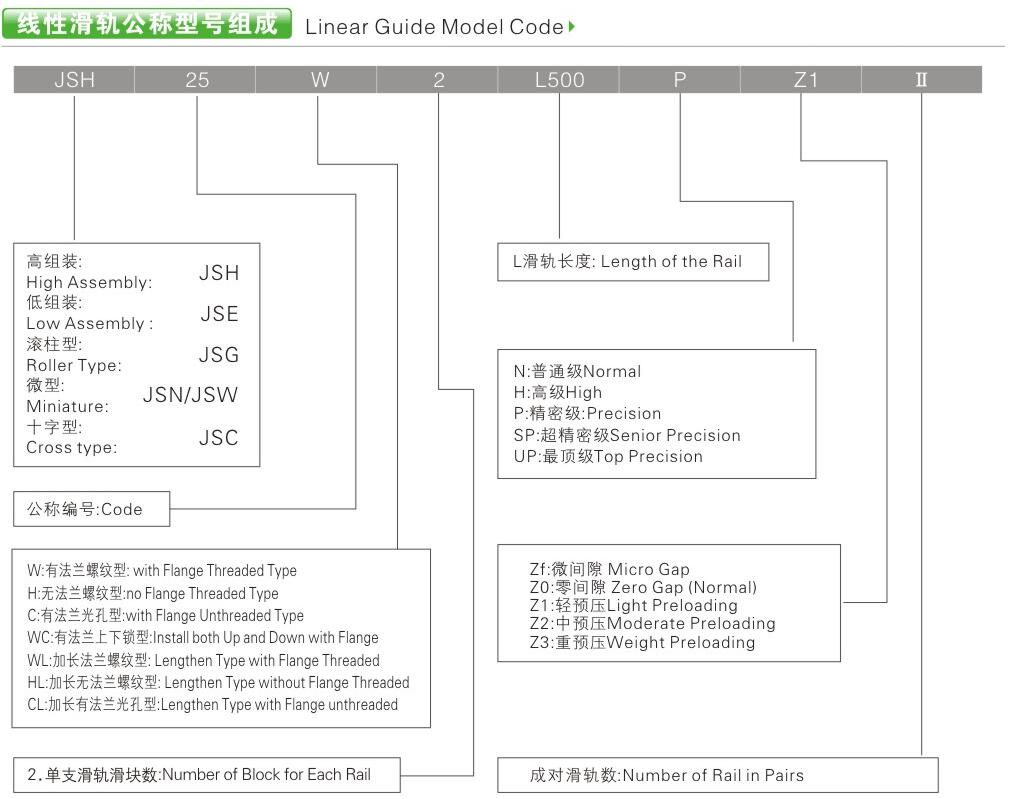

JSH-C, JSH-AC , JSH-ACL linear slide (high group)

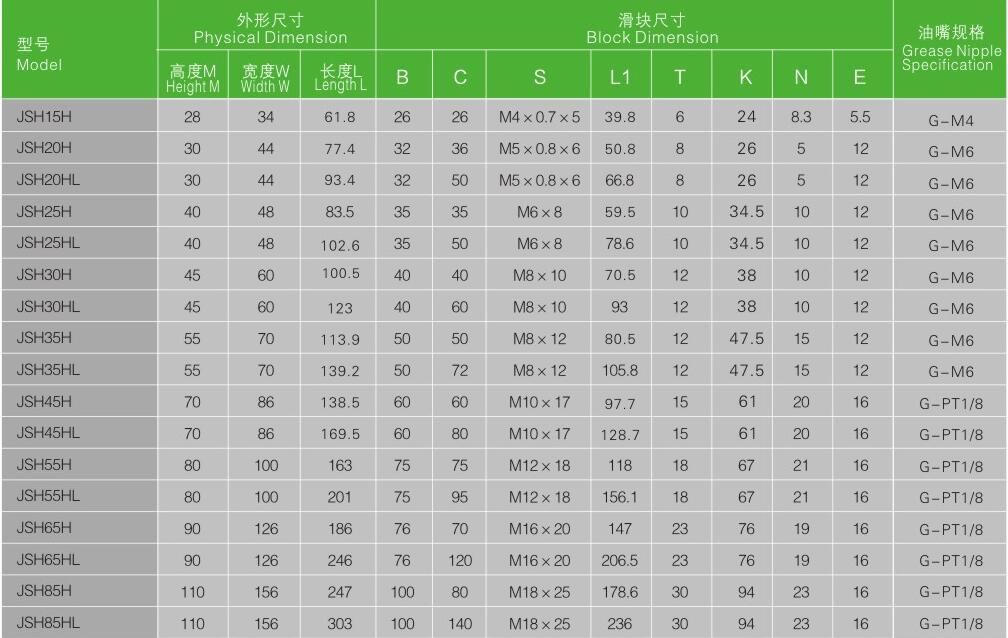

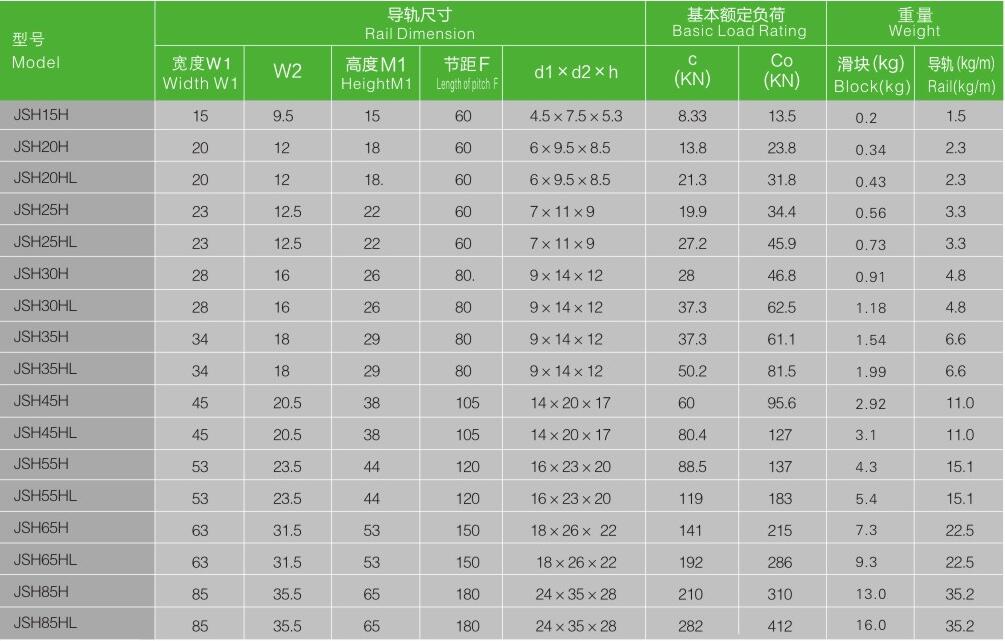

Specification of JSH Sereis(High Assembly)

The flange part is produced with the threaded installation hole which can use the long screw bolt

Same cross section to JSH-W, engthened the block length, enhance the rated load capacity

Product Feature

• Interchangeability

For the tightly control of production precision, all the size can be maintained at a stable tolerance range.So the interchange type linear guide can keep the same smoothness, preloading and precision when the block arbitrarily assemble on the same type of rail. It is very easy to assemble and repair.

• High Positioning Accuracy

When machine that vectoring by linear guide .the friction coefficient will be 1/50 of sliding friction coefficient.as the friction method of linear guide is rolling friction, the disparity of dynamic friction and static friction will become smaller, when machine runs, there will be no slipping phenomenon and the positioning accuracy can reach very high

• Excellent Lubrication Design

Lubrication design patent, can evenly the lubricating grease injection Patent design of Lubricant oil-way can evenly inject lubricating grease to every loo and obtain the optimal lubrication effect under various installation method, it improves the overall running smoothness and service life to achieve the high precision.high reliability and smooth stability of linear motion requirements

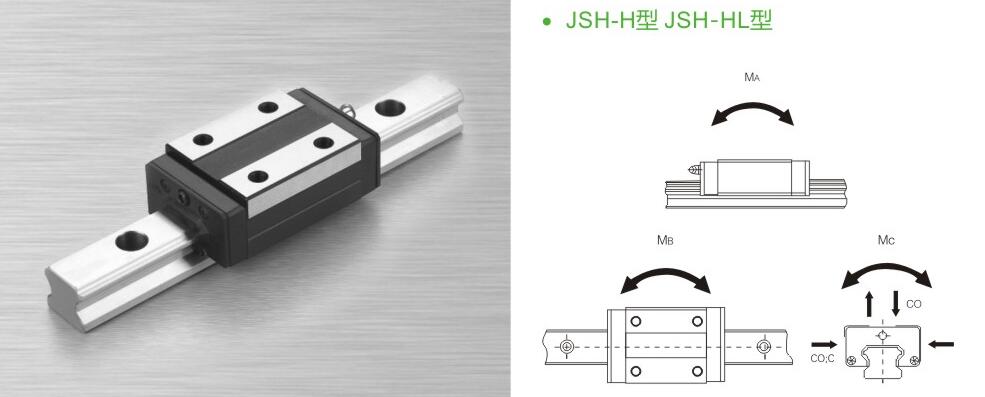

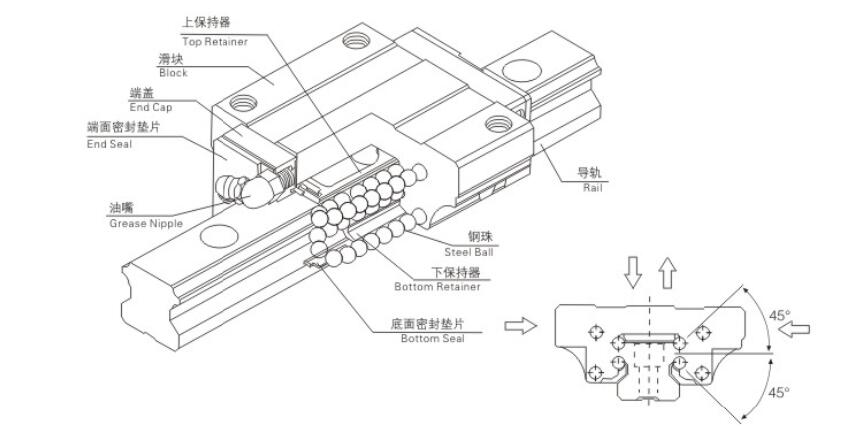

• Four Direction Equal Load Capacity

JSH rail rolling body is to be designed with special pressure angle which make it can bear the same rated load of its radial, anti radial and horizontal direction.

• High Rigidity, High Load

JSH Linear guideway is designed with four columns arc grooves which increase the contact area.compare with two cloumns groove design.it has been greatly improve on the loading capacity, contact stiffness and system rigidity.

• High Precision

JSH linear guideway is produced by high precision special plane which can polyhedrally grind at the same time, detected by laser and other advanced process.all of these guarantee the manufacturing precision of TRH linear guideway.

• Smoothness, Low Noise

The returning device of JSH linear guide adopt a simple and lubricant ball recirculation design with shock resistant circulative accessory –strengthening synthetic resin.the smoothness of the movement is good which achieves a smooth and noiseless linear motion.

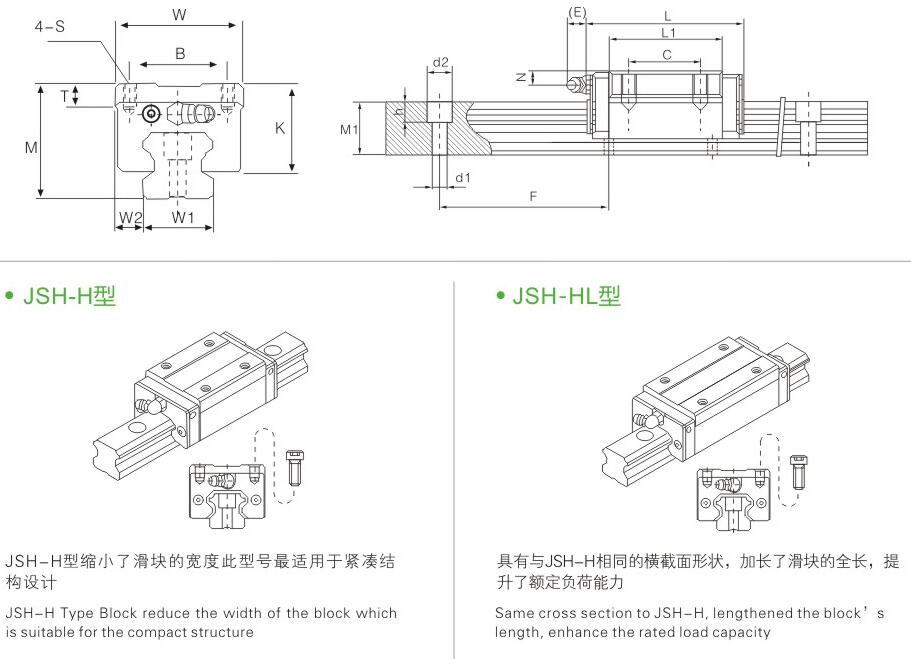

• Compact Structure

The section and rigidity of JSH linear guideway attain the most optimal design which is with a small section but high rigidity,thus achieve the purpose of miniaturization of machine tool.

• Easy Installation

Low requirements of installation guide for JSH users, it is easy for installation and debugging

• With automatic self-aligning capability

Arc groove design of the front combination makes the linear guideway has the ability to automatically adjust the center, even if to give preloading it can absorb installation error, and maintains a high precision,smooth and stable linear motion.

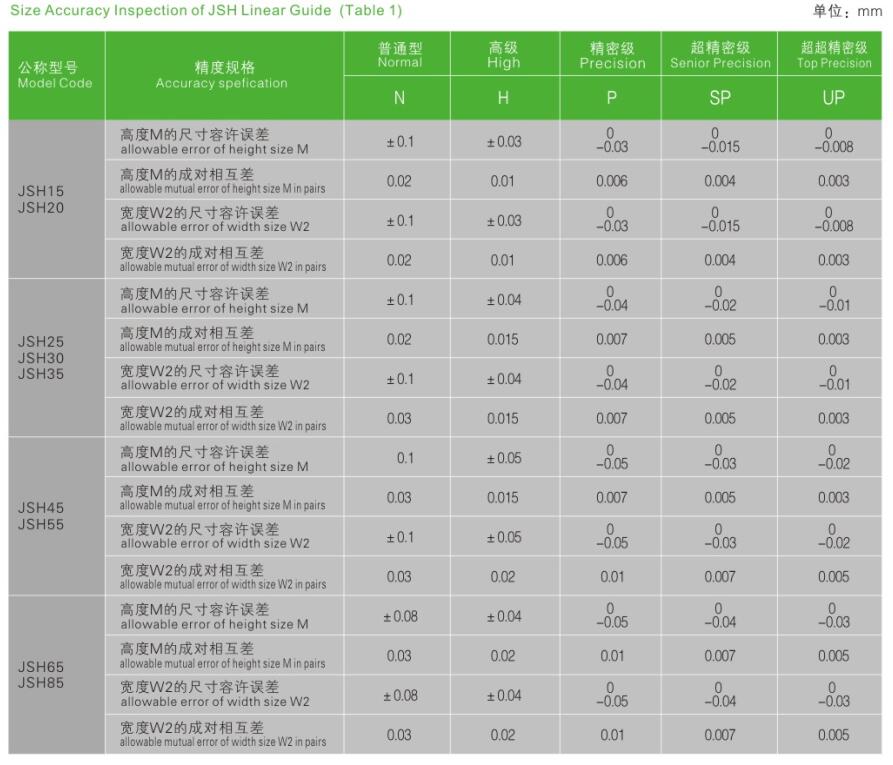

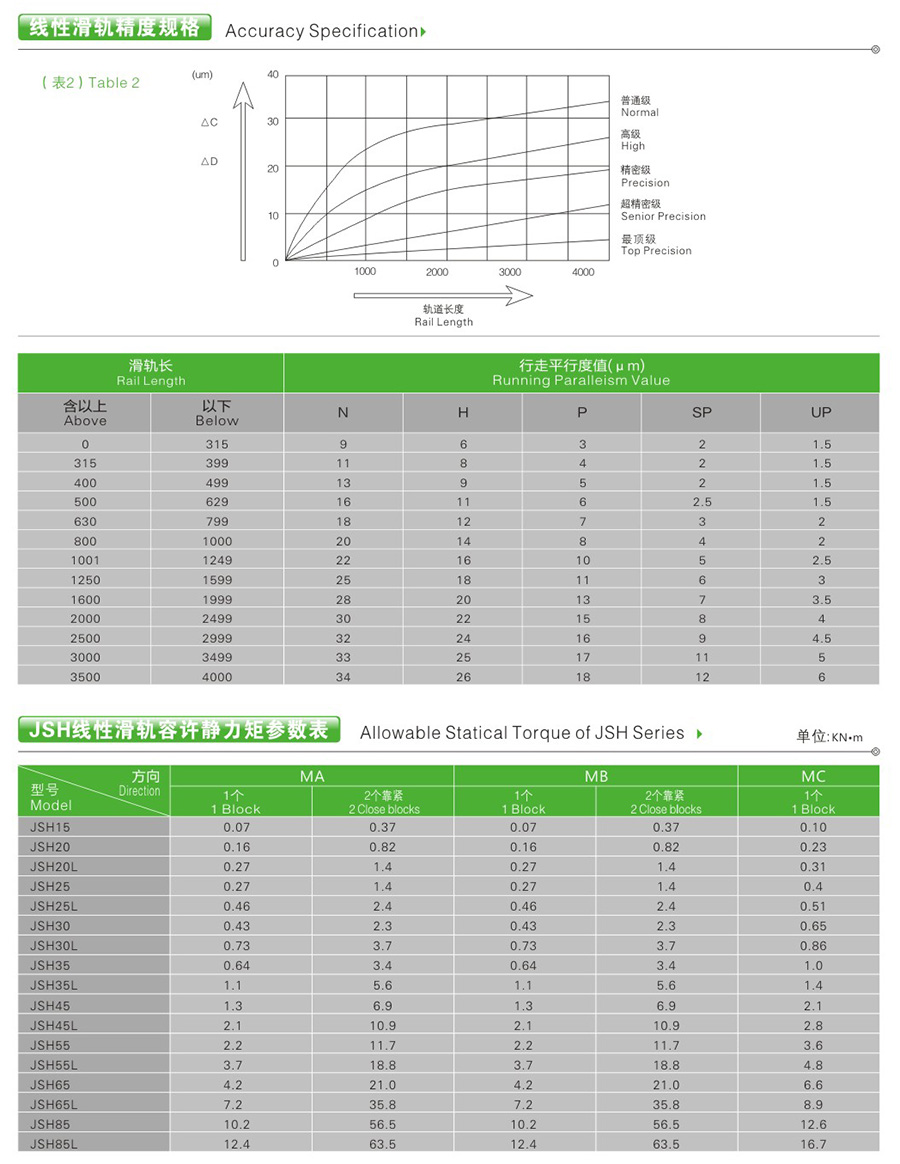

Accuracy for Choose►

Five accuracy grades for choose:Normal/High/Precision/Senior Precision/Top Precision.

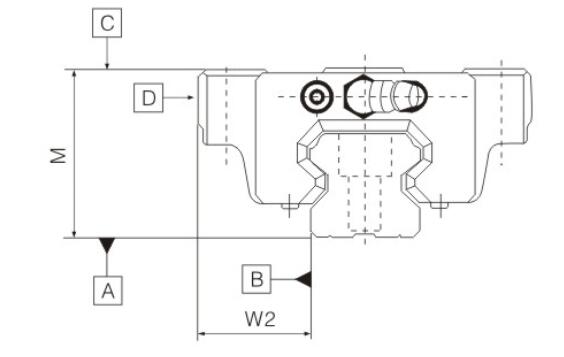

The accuracy of JSH series products are mainly reflected on three aspects: accuracy of running parallelism, accuracy of assembly size, accuracy of the position error of hight and width in pairs( when several blocks used on one rail or several rails install on one plane, the position error of height and width in pairs is prescriptive)

For details please refer to the specification table

Accuracy Specification►

Geometric tolerance and accuracy of JSH type show as table 1 in page AOS and table 2 in page A06, the accuracy of each type is separated into :Normal,High,Precision,Senior Precision,Top Precision.

Size Accuracy Inspection of JSH Linear Guide (Table 1)

Installation Accuracy►

The allowable error of linear guide installation

The block of JSH series has the ability to automatically adjust the center, even if the installation face has a little error, it can still have the smoothly linear motion according different pre-load (such as to meet the following allowable error range). This is the special advantages of JSH series linear guide products

Installation and adjustment of Linear Guide►

Installation and adjustment of Linear Guide►

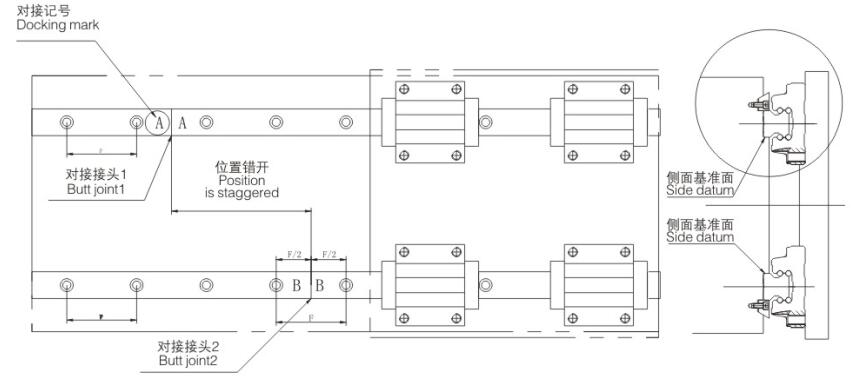

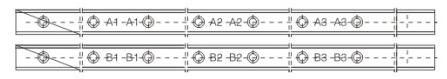

- Distinction of the Lengthened Linear Guide Rail

When rail that need to joint to be lengthened, we will write the same capital on one set rail, and the continuous Arabic numerals to indicate the joint sequence, the joint end mark the same arabic number (as showed in picture)

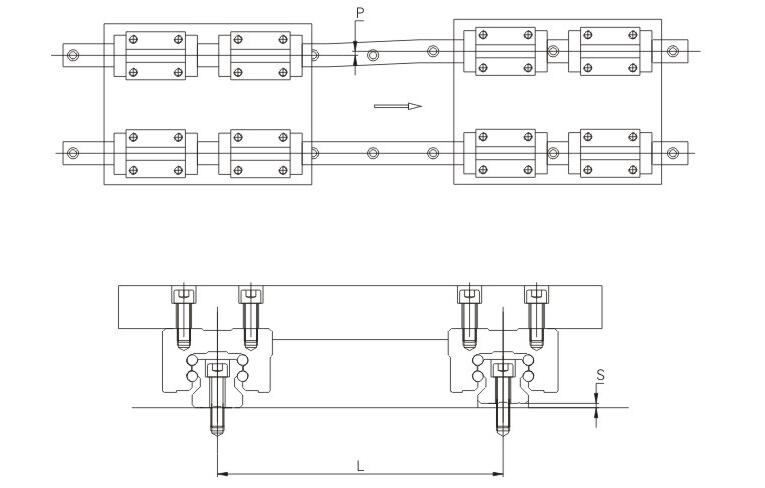

- Pairing the use of docking rails

1.rail mounting base should have a base and side datum.

2.the docking part in accordance with the docking mark stitching docking connector should be staggered to install.

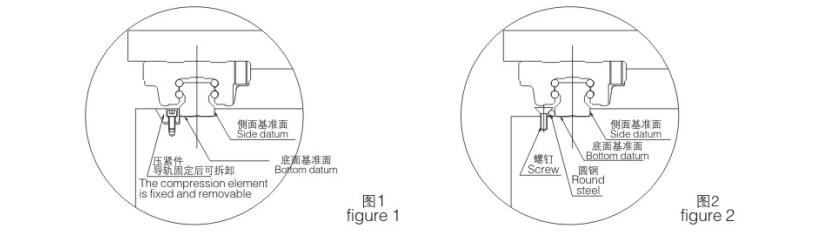

3.rail installation side of the base surface should be installed when the pressure to ensure that the side surface and ensure that the surface coincide. (Specific installation diagram shown in Figure 1, Figure 2)

Installation and adjustment of Linear Guide ►

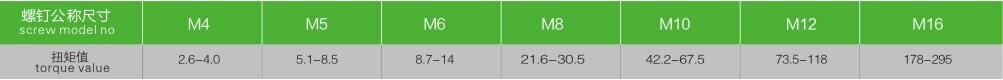

- When tightening the bolt, should use a constant torque wrench and install as the recommend torque value as the following table:

- Protection of Rolling Linear Guide

Because of the scope of application of linear guide is expanded,various conditions, applications are required to use, in order to adapt to different user’ s requirements of seal protection, special designed as following various sealing mode is for select, please distinguishing when make the order.

If the work environment is very bad, and the space allow, in addition to make use of to play tricks of seal completely, also adapt to consideration increment the dust palliative”skin tiger* device(is like diagram)

- The Lubrication of Rolling Linear Guide

The main purpose of linear guide lubrication is to reduce friction and wear in order to prevent overheating from destruction of its internal structure which will effect the motor function of linear guide. Rolling linear guide have been filled with high lubricating grease prior to shippment, to ensure good lubrication during operation, but in order to avoid the loss of lubrication caused by the lack of lubrication , recommend a regular supplement when the slider stroke is 50km . When the rounning speed of linear guide is for high speed (V≥ 35m/min), recommend to use of N32 lubrication or connect by pipe to forced lubrication (show as in picture). For low speed ( V ≤ 35m/min) .recommend to use the lithium lubricating grease

When used in Low speed occasion, it is strictly prohibited to cleaned the lubrication of the internallinear block by the gasoling before installation to avoid the falure of lubrication that add prior to shippment.

Linear Slide Dustproof Accessories ►

- In the presence of dust and iron, if there is foreign matter in the linear motion system of the slider, it may cause abnormal wear inside the slider, shorten the service life and affect the smoothness of the linear motion of the slider. Measures to prevent the entry of foreign matter.

- Dust-proof products are for the existence of dust, wood chips, iron and other impurities in the bad environment, the product configuration of a high degree of dust-proof dust-proof accessories, if customers in the above environment similar to the use of slides. When the dust is configured, add a seal code after the product slider type number.

|

Seal code |

Sealing method |

Dustproof accessories |

Application |

|

U |

End seal |

Scraper board |

Precision detection equipment and other dust-free environment |

|

UU |

End seal + Bottom seal |

Scraper board + bottom dust film |

Conventional sealing occasions |

|

UX |

End seal + metal scraper |

Scraper board + metal scraper |

There are iron, sparks and other occasions |

|

UUX |

End seal + metal scraper +Bottom seal |

Scraper board + metal scraper+bottom dust film |

There is dust, iron, sparks. Impurities and other occasions |

Note: Where U sealed form for the conventional seal form, when the order can not be marked.

- Dust resistance value

JSH … UU-type slider (internal lubricant), the average resistance of each dust-proof device,Please refer to the dust resistance table.

| Nominal model |

[ViaxifTium, resistance value |

Nominal model |

iviaximurn, resistance value |

|

15 |

2 |

45 |

19.6 |

|

20 |

2.5 |

55 |

19.6 |

|

25 |

3.9 |

65 |

34.3 |

|

30 |

7.8 |

85 |

34.3 |

|

35 |

11.8 |

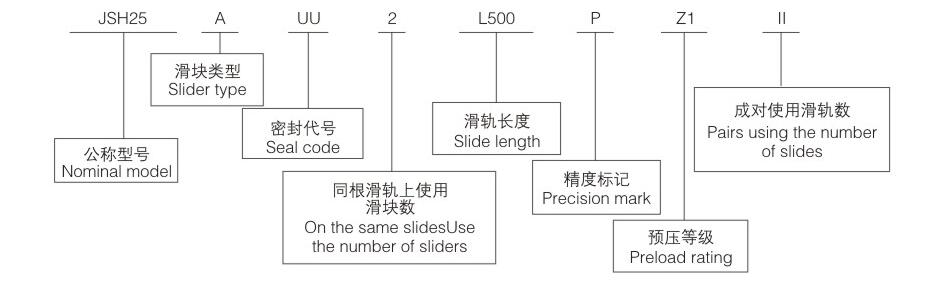

- Nominal model number

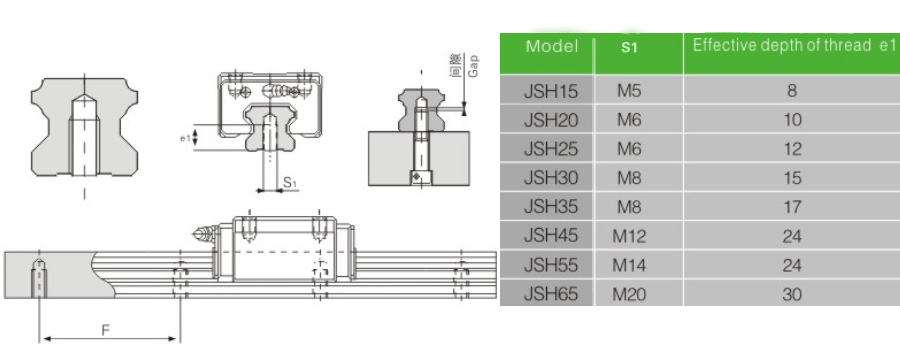

JSH Series Linear Guide with Bottom Installiation Thread Hole ►

JSH series linear guide includ the follow type linear rail which is processed the threaded installation holes at the bottom of the rail. It is more suitable for that need to install the rolling linear guide from the bottom or improve the dustproof performance.

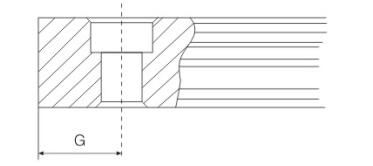

When select the length of the bolt, the end of the bolt and the bottom of the thread (the effective depth of thread) need to have a gap of 2 to 5 mm (refer to the above picture)

Standard pitch of thread F size please refer to the table of page A15 – Pitch F

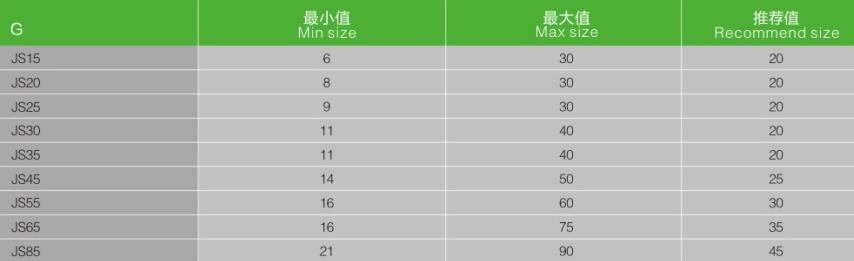

Specification of G Figure ►

Too small for G value will affect to machine the flat wiper hole of the rail end

Too big for G value will affect the stability and accuracy of the rail end

According to the actual usage, recommend the following dimensions to the user.